Introduction: Think Seasonally to Protect Your Denver Chimney

Chimneys in Denver, Colorado, face a demanding climate that shifts from dry summer heat to sudden snow and freeze–thaw cycles. Thinking seasonally makes chimney care manageable and more effective. By aligning inspection and repair tasks with the weather and your home’s heating schedule, you can address problems before they escalate and preserve the performance of your fireplace or stove. Use this seasonal roadmap to pace your work across the year and, when needed, bring in experienced chimney repair support to handle complex or high-risk projects.

Below, you will find Denver-tailored steps for spring, summer, fall, and winter. Each season has goals, from post-snow assessments to pre-winter validation. Along the way, you will see safety reminders, materials tips, and quality checks that improve durability and performance.

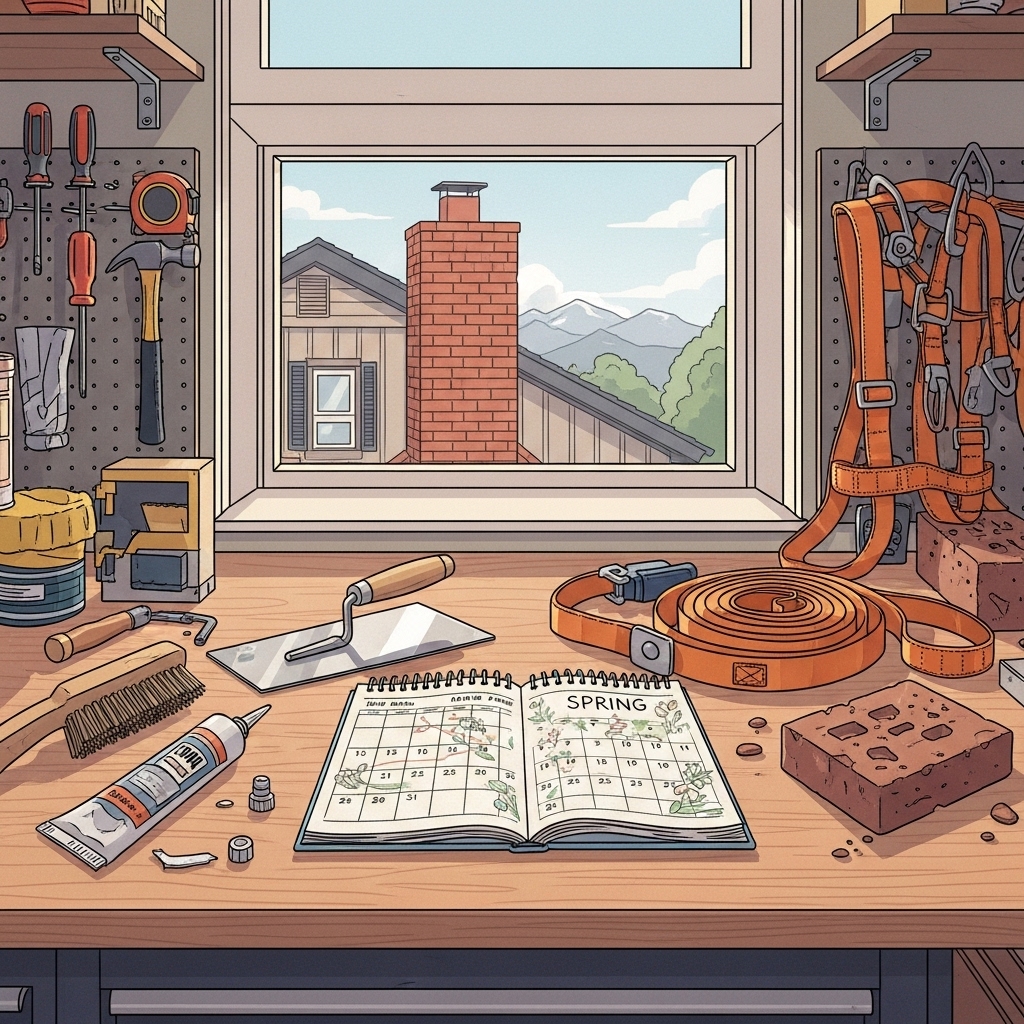

Spring: Assess, Document, and Plan

After a Denver winter, your chimney has endured snow loads, wind, and freeze–thaw cycles that exploit any weakness. Spring is the time to take stock and plan repairs for warm-weather windows.

- Ground scan: Use binoculars to identify crown cracks, missing caps, spalled bricks, or leaning stacks.

- Attic check: Look for moisture stains or rust on fasteners near the chimney. Damp insulation indicates flashing leaks.

- Firebox and smoke chamber: Inspect for loose mortar, rough parging, and damper issues. Note any odors that may suggest moisture entry.

- Documentation: Photograph defects and rate severity. Create a list of materials and tools for summer repairs.

- Safety preparation: Service ladders, harnesses, and anchors. Replace worn PPE and label gear for quick setup during summer.

Summer: Execute Masonry Repairs and Upgrades

Summer brings stable weather and predictable cure times—ideal for masonry and exterior work. Prioritize structural and water-management tasks.

- Repointing: Rake and refill failing mortar joints with compatible mixes. Protect fresh mortar from rapid drying with shade and light misting as needed.

- Crown repair: Patch or rebuild with freeze–thaw rated materials. Retain a flexible joint around the flue to accommodate expansion.

- Flashing and counterflashing: Seal small gaps with elastomeric products; replace failed sections by cutting a clean reglet and properly lapping metal.

- Cap installation or replacement: Choose durable stainless steel with appropriate mesh. Verify secure fastening and draft clearance.

- Waterproofing: After repairs cure, apply a breathable silane/siloxane repellent to exterior masonry to reduce water absorption.

Quality checks matter. Hose-test flashing gently, inspect the attic after a summer storm, and keep a log of work dates and materials. If you uncover extensive instability or liner damage, pause and line up professional help familiar with Denver code requirements.

Fall: Validate and Prepare for Heating Season

As temperatures drop, confirm that summer repairs held and that your system is safe and efficient before heavy use.

- Draft and odor check: Start small fires to observe smoke movement and detect any unusual smells.

- Damper function: Ensure smooth operation and full closure to reduce heat loss when not in use.

- Cap and crown recheck: Look for any new stress cracks or fastener loosening after summer heat.

- Interior surfaces: Verify smooth smoke chamber parging and intact firebrick joints.

- Safety equipment: Test smoke and carbon monoxide alarms and confirm clearances around combustibles.

Winter: Monitor and Maintain

During winter, limit exterior work to emergencies, but stay vigilant. Monitor performance and keep a close eye on moisture patterns inside.

- Observation: Watch for smoke spillage during wind events, unusual odors, or new stains on ceilings or walls near the chimney.

- Snow management: Clear heavy snow buildup away from the chimney area if safe to do so from the ground. Avoid climbing in icy conditions.

- Fuel practices: Burn seasoned wood to minimize creosote. Do not attempt to “burn out” creosote; it is dangerous and ineffective.

- Emergency readiness: If leaks appear or masonry shifts, contact a professional quickly to prevent interior damage.

Safety Fundamentals Across All Seasons

- Weather windows: Choose calm days and avoid gusts common in Denver afternoons.

- Fall protection: Always use a properly rated harness and secure anchors. Keep your lanyard short to minimize swing falls.

- Tool staging: Leash tools, use a haul line, and maintain clean work zones to prevent trips and drops.

- Fire safety: Extinguish fires and let components cool fully before inspection or repair.

- Respiratory protection: Wear a respirator when cutting, grinding, or cleaning masonry and liners.

Materials and Techniques That Last in Denver

Durability starts with compatible materials and careful application. Use mortar matched to your brick’s hardness, freeze–thaw resilient crown products, elastomeric flashing sealants, and breathable water repellents. Apply coatings and mortars during temperature ranges recommended by the manufacturer and protect fresh work from sun and wind. Document cure times to avoid premature exposure to rain or overnight freezes.

Mid-Year Review and Course Corrections

Midway through the year—typically after your summer projects—evaluate the overall condition again. Confirm that repointing is intact, crowns are uncracked, and flashing is sealed. If any element underperforms, adjust your plan. For homeowners who prefer added certainty, align with dependable chimney repair services familiar with regional materials and inspection standards.

Common Mistakes to Avoid

- Using overly hard mortar on older, softer brick.

- Rigidly sealing the crown–flue interface instead of using a flexible, high-temperature sealant.

- Applying non-breathable sealers that trap moisture.

- Skipping flashing checks because they “look fine” from the ground.

- Working on windy or icy days without proper fall protection.

Frequently Asked Questions

Q: What is the best season for masonry repairs in Denver? A: Summer typically offers the most stable conditions for curing, with spring and early fall also workable if you plan carefully.

Q: Do I need to waterproof every chimney? A: Not always, but for windward exposures or older masonry, a breathable repellent after repairs can significantly reduce water absorption and freeze–thaw damage.

Q: How often should I inspect my chimney? A: Perform a full inspection annually and after major storms, then validate repairs before heating season.

Q: Can I replace flashing myself? A: Minor sealing is possible for DIYers with roofing savvy, but full counterflashing replacement often requires professional tools and experience.

Q: Are metal chimneys easier to maintain? A: They have different maintenance needs and strict manufacturer requirements. Do not mix components across brands or models.

Q: What indicates a draft problem? A: Smoke spillage, difficulty starting fires, or odors when the appliance is idle. Cap design, chimney height, and house pressure can play roles.

Keep Your Chimney on Schedule

Approach chimney care as a year-round process: assess in spring, repair in summer, validate in fall, and monitor in winter. With the right timing, materials, and safety practices, you can extend the life of your chimney and maintain safe, efficient heat. When a project exceeds your comfort or tools, partner with a local specialist and arrange timely chimney repair to safeguard your home through every season.